Robotic Construction

Additive Manufacturing-

-

This technology may or may not be appropriate for additive manufacturing but here are some thoughts:

-

Standard 3D Printers have an assembly speed on the order of n^3 (with tiny pixels).

-

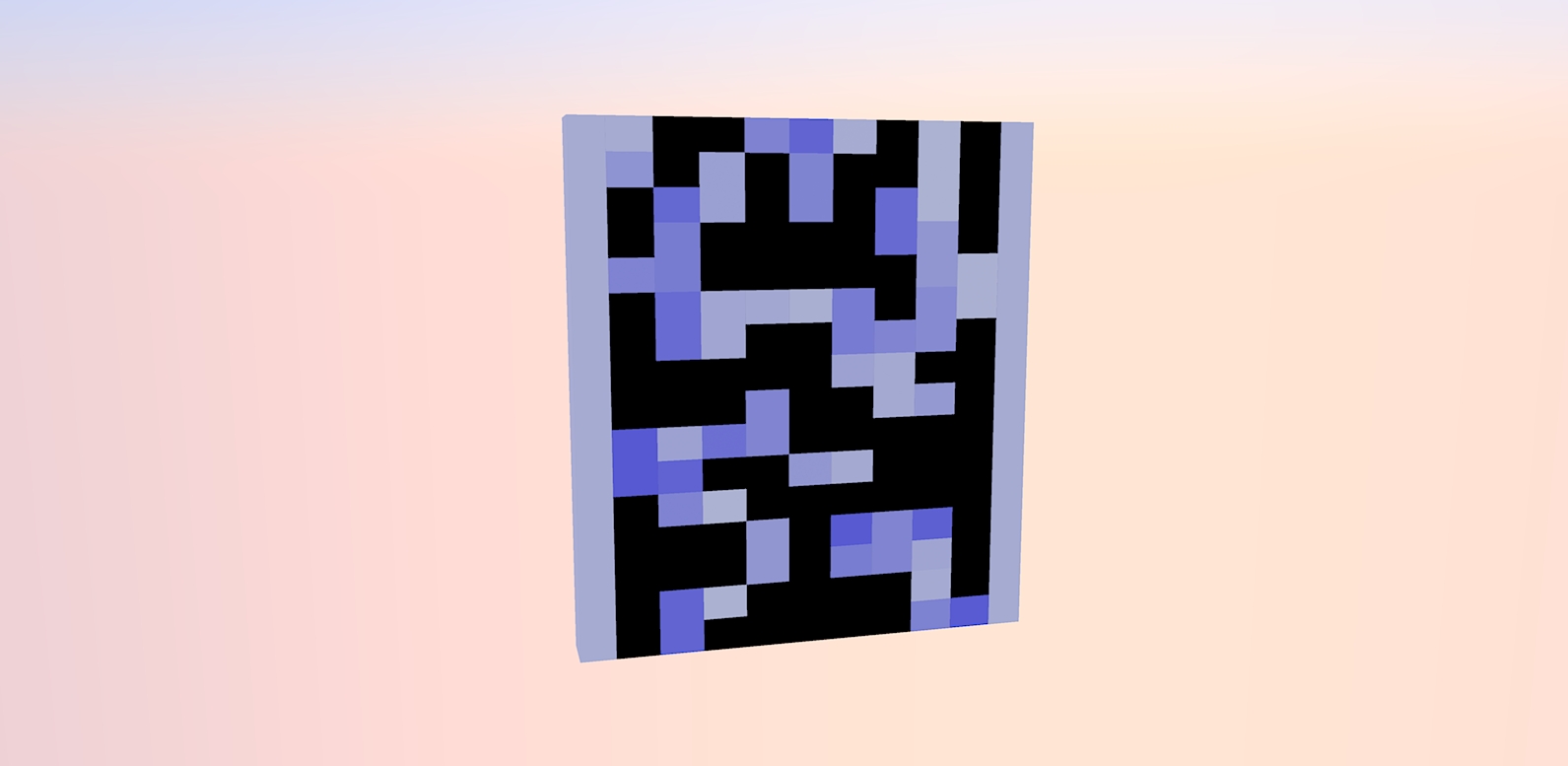

An extrusion array would build a volume on the order of n^2 (with cell profiles).

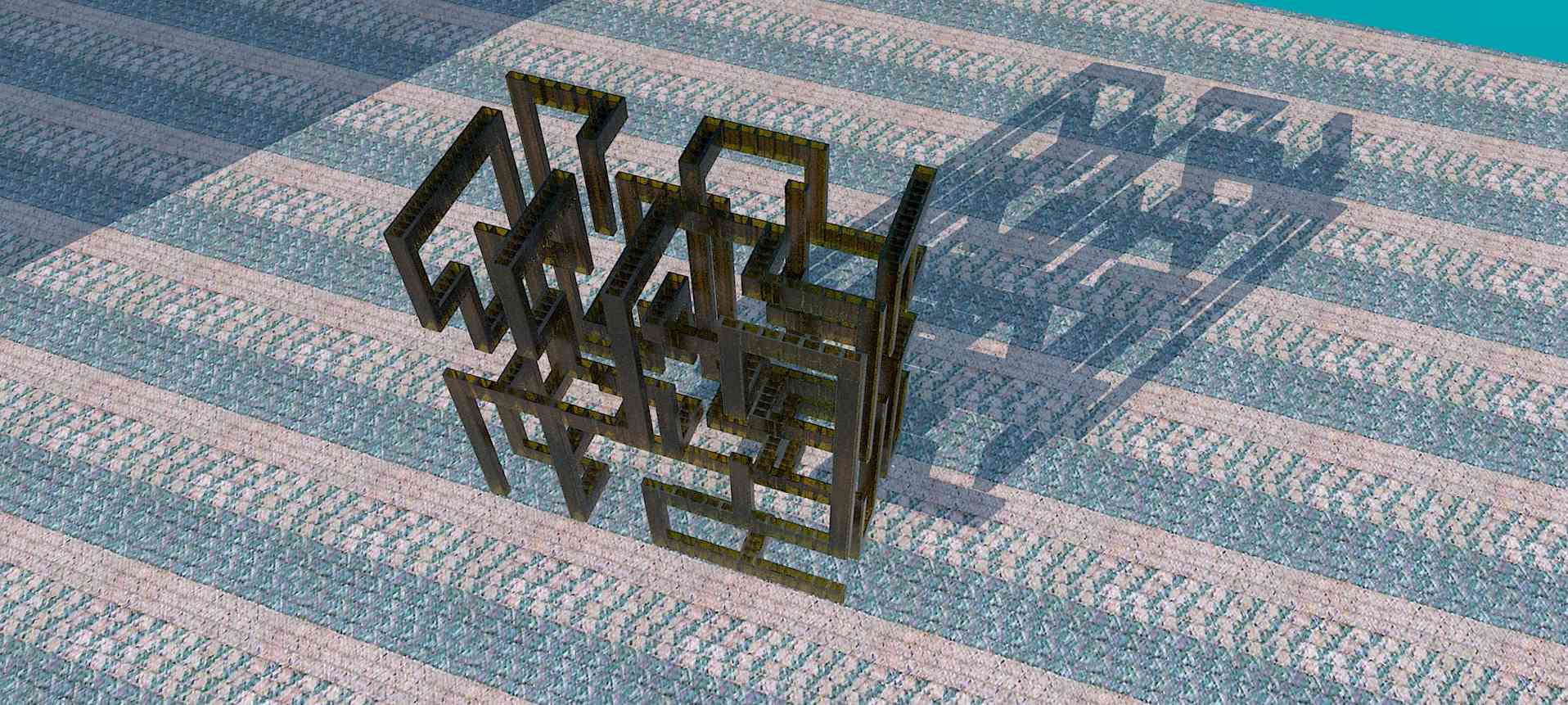

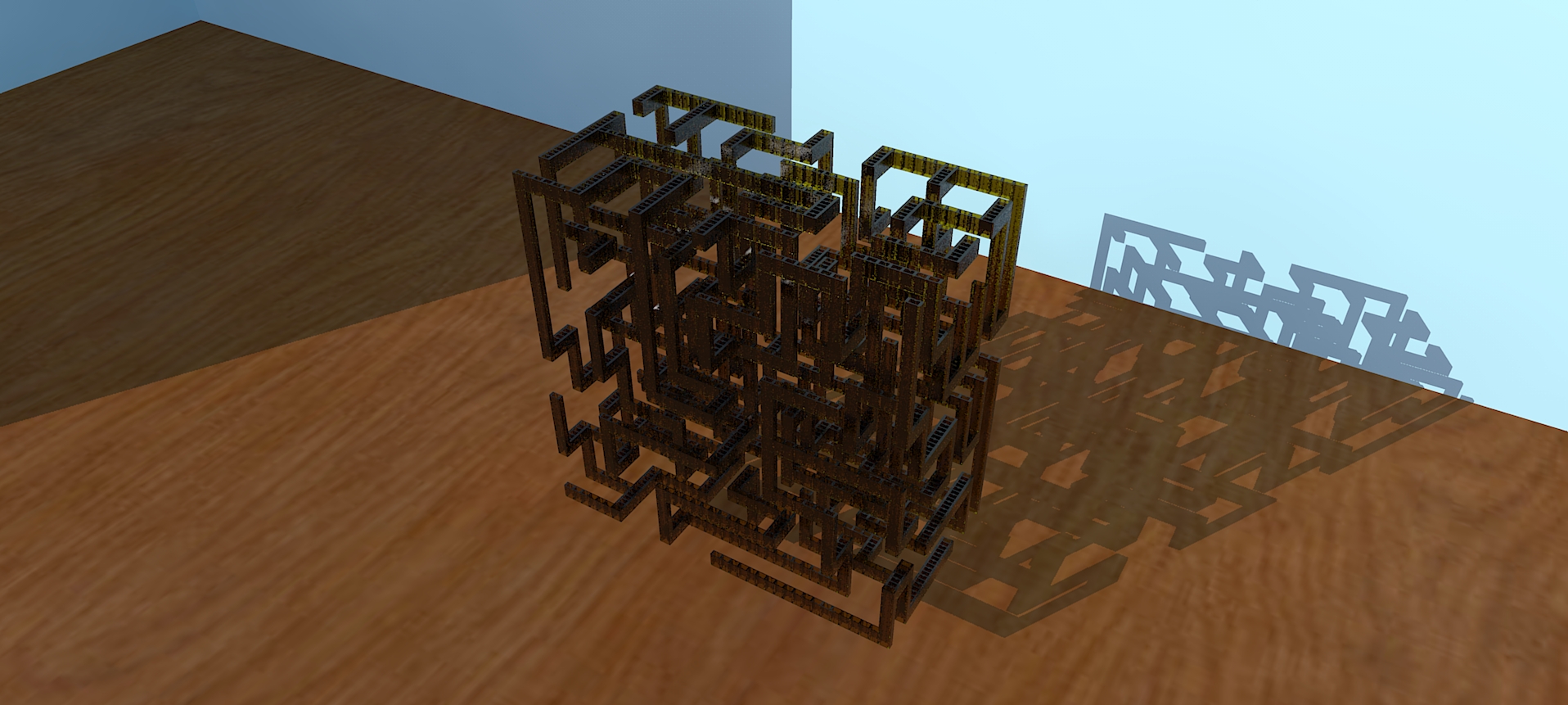

Robotic construction of large structures seems possible.

There robot or mechanism would have two types of environments to contend with, on ground or in space.

Regardless, precut, shaped, and assembled sub-sections would need to be prepared.

-

First, is on the ground with gravity. In this case a crane like mechanism would need to place individual extruded parts into the structure. The parts can be snapped together or slid together. This means a "two hand" device is needed.

-

Second, is the space environment.

TBD

The first step is to define the shape of the structure. This is a bit tricky because parts of the stucture can follow a curved path with bends and twists. Other parts can be rectalinear. That would be walls, floors, or small assemblies such as compartments, frames, or shelves. The algorithms would have to be pretty clever to decide when to change the direction of the primary extrusion axis or change the master profile scale or shape.

Assembly Robot Simulation Project Here